Laisser un avis

Aide · Région

Créer un Hangout

Profile

David Martin

Employeur actuel : Johnston Press

Lieu de résidence : Leeds

79 abonnés|367 803 consultations

BioPostsPhotosYouTube

Stream

David Martin

Questions/Help -A little advice please.

I have got my 3DR printing nicely now but am now keen to explore building another printer with a larger print volume. I know there are extensions available for the 3dr but I'm not convinced that the rigidity of an extended 3dr will be sufficient.

Whatever I choose, I intend to use:

Smoothie based controller

V-slot rails

Octopi

FSR or inductive Z-probing

Possible upgrade to heated bed but not needed initially.

For deltas, I'm currently considering either a v-slot kossel variant or something like the Griffin.

I'm also looking at CoreXY options but I can't find a consensus on a good design to build on.

Can anyone give me recommendations for either option? The diversity of options is fantastic but makes it difficult to find a conclusion on what's best.

Thanks in advance.

adavidm

I have got my 3DR printing nicely now but am now keen to explore building another printer with a larger print volume. I know there are extensions available for the 3dr but I'm not convinced that the rigidity of an extended 3dr will be sufficient.

Whatever I choose, I intend to use:

Smoothie based controller

V-slot rails

Octopi

FSR or inductive Z-probing

Possible upgrade to heated bed but not needed initially.

For deltas, I'm currently considering either a v-slot kossel variant or something like the Griffin.

I'm also looking at CoreXY options but I can't find a consensus on a good design to build on.

Can anyone give me recommendations for either option? The diversity of options is fantastic but makes it difficult to find a conclusion on what's best.

Thanks in advance.

adavidm

1

2 commentaires

Thanks. I'll take a look at the three you mentioned. I picked the 3DR almost at random and luckily it is a well sorted design with few issues.

I can't believe I'd be that lucky again so keen to get advice before plunging ahead as this printer will probably be the last for a while at least. My wife has been tolerant of my hobby thus far but no point pushing my luck!

Cheers

adavidm

I can't believe I'd be that lucky again so keen to get advice before plunging ahead as this printer will probably be the last for a while at least. My wife has been tolerant of my hobby thus far but no point pushing my luck!

Cheers

adavidm

· Traduire

Ajoutez un commentaire...

David Martin

Questions/Help -Building a new set of arms for my +Richard Horne 3DR. Bought a set of these adjustable aluminium rods as an experiment.

Has anyone else tried these? If so, anything to look out for particularly?

Has anyone else tried these? If so, anything to look out for particularly?

15

1

7 commentaires

That's a nice solution. A drop of superglue may be required when they are calibrated.

· Traduire

Ajoutez un commentaire...

David Martin

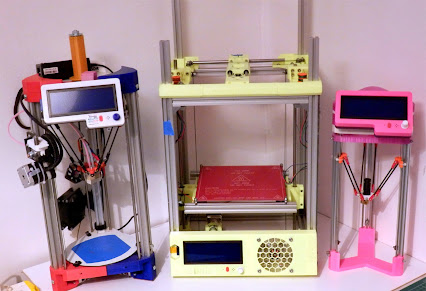

Show-n-tell -It lives! My 3DR is up-and-running nicely. Thanks to +Richard Horne for the printer design and +Jay Couture for his essential calibration video(s).

I designed some simple add-ons to the 3DR to fit the spool, RAMPs, fans, FSR bed and LCD. If anyone is interested, they can be found on YouMagine: https://www.youmagine.com/users/adavidm although I've not had time to upload them all yet.

adavidm

I designed some simple add-ons to the 3DR to fit the spool, RAMPs, fans, FSR bed and LCD. If anyone is interested, they can be found on YouMagine: https://www.youmagine.com/users/adavidm although I've not had time to upload them all yet.

adavidm

12

Looking fantastic!

· Traduire

Ajoutez un commentaire...

David Martin

Show-n-tell -My brother and I decided to have a go at lost-PLA aluminium casting this weekend. This is our first try, really happy with the outcome. Yes, I could have spent longer polishing the z-lines but a) I kind of like how they look and b)I'm lazy.

edit: Model is Woman Torso Sculpt, by Meoworks.

edit: Model is Woman Torso Sculpt, by Meoworks.

48

5

20 commentaires

I've been working on an extensive post on this; here is the short story:

Coal will do for melting the aluminum (if you have a fan to supply air).

PLA is the least favorable print material, I've yet to try HIPS but other posts suggest it probably will perform the best (currently leading is SLA (SF makerjuice)).

Plaster-sand mix depends on the sand, I recommend trying 40% to 60% sand, water mix depends on the plaster (when you add sand to the plaster/water mix, you need to add more water too).

Try to prevent the water/other-materials from turning into gasses when pouring and you should do good. PLA will stick to the insides of the mold and aluminum won't vaporize the PLA, so you need other methods of removing the PLA.

Coal will do for melting the aluminum (if you have a fan to supply air).

PLA is the least favorable print material, I've yet to try HIPS but other posts suggest it probably will perform the best (currently leading is SLA (SF makerjuice)).

Plaster-sand mix depends on the sand, I recommend trying 40% to 60% sand, water mix depends on the plaster (when you add sand to the plaster/water mix, you need to add more water too).

Try to prevent the water/other-materials from turning into gasses when pouring and you should do good. PLA will stick to the insides of the mold and aluminum won't vaporize the PLA, so you need other methods of removing the PLA.

· Traduire

Ajoutez un commentaire...

David Martin

Questions/Help -Any ideas what causes this detachment of filament at intersections? Steps/mm seems ok, filament diameter ok. Infill lines look a little thin too. I tried over extruding by 20% but no improvement. Could it be a blocked nozzle?

Thanks in advance.

adavidm

Thanks in advance.

adavidm

7

1

31 commentaires

Hmm, here is one. Not sure the results justify the complexity, or the price. But it exists:

http://www.3ders.org/articles/20140116-dc-motor-powered-rapy-3d-printer-made-in-korea.html

http://www.3ders.org/articles/20140116-dc-motor-powered-rapy-3d-printer-made-in-korea.html

· Traduire

Ajoutez un commentaire...

David Martin

Questions/Help -Does anyone recognise the dual hot-end setup on +Richard Horne 's 3DR shown in his blog post from 8th July? Knowing RichRap it's a devious device of his own imagining but wondered if anyone else had tried this setup on a 3DR. Hard to imagine fitting dual hot-ends into the tiny space under the micro-platform. I'd ask direct but I suspect I bombarded him with enough questions already....

Big, Small, Wide, Tall, You have brains in your head. You have tools you can use, you can design a 3D printer any way you choose :) - thanks for the positive thinking Dr Seuss. This is a summary post, going over some of the...

5

4 commentaires

Sanjay Mortimer

+

2

3

2

3

2

Further to what +Richard Horne says, we are still developing the mixer, and ploughing some serious time and cash into doing so. We should have a not-quite-mixer on the market very soon, in fact I just got alpha hardware in the door this morning from manufacture.

True mixing is going to require a consortium effort all the way from raw resin, through filament manufacture, slicing, firmware, hotend, machine to move hotend etc. It's something we're already making headway and are collaborating with some big names already. It will happen. I don't know when it will happen, but I'm trying my darndest to make it happen sooner rather than later.

True mixing is going to require a consortium effort all the way from raw resin, through filament manufacture, slicing, firmware, hotend, machine to move hotend etc. It's something we're already making headway and are collaborating with some big names already. It will happen. I don't know when it will happen, but I'm trying my darndest to make it happen sooner rather than later.

· Traduire

Ajoutez un commentaire...

David Martin

Questions/Help -A little advice needed please. I am building a Richrap 3DR printer and am trying to decide how to cool the cold end of the nozzle. A 40mm fan seems the most common route but I can't find any clear pictures showing how people are mounting them. Can anyone share an STL or photo of a fan mounted to a 3DR micro platform please?

Alternatively, I was looking at attaching a blower fan to the rear of the frame and ducting air through tubing to the cold end, has anyone tried this on a delta? I imagine the weight of the tube is greater than simply mounting a fan but thought it was worth looking at.

thanks in advance.

adavidm

Alternatively, I was looking at attaching a blower fan to the rear of the frame and ducting air through tubing to the cold end, has anyone tried this on a delta? I imagine the weight of the tube is greater than simply mounting a fan but thought it was worth looking at.

thanks in advance.

adavidm

2

9 commentaires

ah sorry Richard G, that was aimed at Richard H!

I did check out the thingiverse link you provided, and I'll probably do something similar once I've got the basic printer working with the JHead have right now. It looks like people use a very simple mount with the J Head, I just can't see a clear photo of it.

Thanks for everyone's continued assistance, much appreciated!

adavidm

I did check out the thingiverse link you provided, and I'll probably do something similar once I've got the basic printer working with the JHead have right now. It looks like people use a very simple mount with the J Head, I just can't see a clear photo of it.

Thanks for everyone's continued assistance, much appreciated!

adavidm

· Traduire

Ajoutez un commentaire...

Contacts

Dans ses cercles

98 contacts

Adresses

Domicile actuel

Leeds

Liens

YouTube

Autres profils

Parcours professionnel

Profession

IT Director

Emplois

- Johnston Pressprésent

Informations générales

Sexe

Homme

Applications avec Google+ Sign-in

- Sky Force 2014