Check out this 3D printer (translated) which [Arkadiusz Śpiewak] has been working on. When sending in the tip about his project he made the important distinction that it isn’t finished, but he has reached that critical threshold where he has printed items with it.

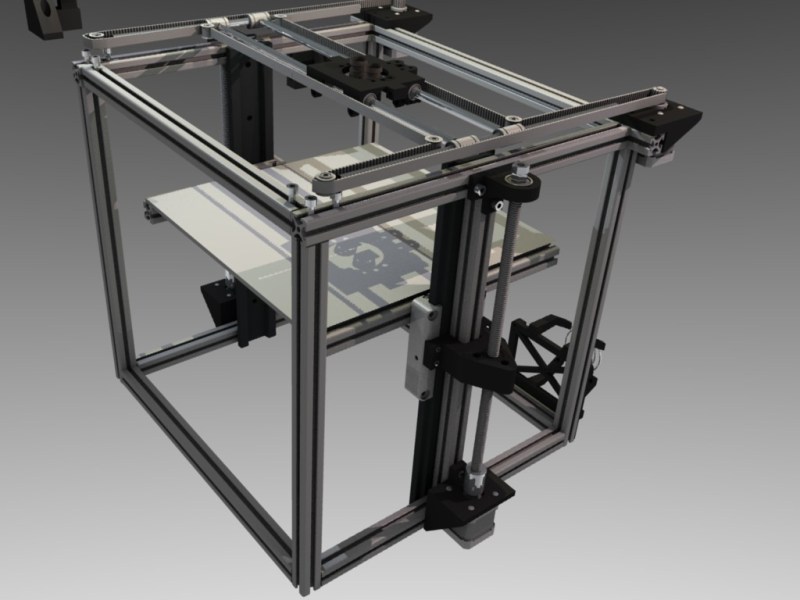

He decided to go with a design that is sometimes referred to as an H-bot. If you’re completely unfamiliar with it, you may find this H-bot design article helpful. The gist of it is that this technique makes it so that the motors used to move the extruder along the X and Y axes are themselves stationary. One large timing (toothed) belt makes a circuit around the top of this cube in the shape of the letter H. This is a bit easier to see in [Arkadiusz’s] rendered image found after the jump along with video of an early print test.

The Z axis uses two motors mounted along the bottom of the cube. These raise and lower the bead, instead of moving the extruder itself. All-in the printer should have a maximum object size of 30x30x30 centimeters. It’s being driven by a Smoothieboard, which was mentioned quite a bit when we were discussing using the RA driver board with a 3D printer.

Isn’t this true for most 3D printers? I believe the MakerBot ones move the bed as well?

Yes, makerbot replicator, ultimaker, tauntillus are moving bed in Z axis. But on replicator you are also moving X motor. And on ultimaker and tauntillus x-y gantry cant take to much load, thats why they are using bowden extruder.

On h-bot i get both, lght weight x-y gantry, but also enough strenght to have direct drivern extruder, or even dual one.

Its just diffrent design, it has it good and bad sides.

The Ultimaker gantry can take quite a load actually. The reason they use a bowden extruder is to keep it light for faster acceleration.

In addition to the consumer/hobbiest 3d printers, most commercial 3d printers move Z instead of everything else.

The RepRap Mendel (and its many derivatives) uses a bed that is stationary on the Z axis to make it more compact.

The smoothieboard site doesn’t look like it’s been updated for a while. Anybody know how active the project is?

The wiki ( documentation ) itself is updated often, but we don’t use the blog much because it’s not very convenient to use. I’ll put some work into that, and start doing more frequent updates.

The community really revolves around the IRC channel ( #smoothieware @ irc.freenode.net ), the website is just for documentation.

Isn’t weight distribution an issue in this setup?

In what way? Mass thats moving on this printer is very low comparet to prusa, on h-bot only x axis and extruders are moving with fast speed. All stepper motors are stationary besides extruder one. Misumi 20×20 profiles are also very rigit.

Aslo i have ability to use big nema 23 motors, that are cheaper for same or greater torque, and im not addind any payload.

Well, if the mass of the object being printed isn’t centered on the table’s horizontal axis it’ll cause a tilt. It’s a fairly big table on a fairly narrow support.

Look at that big fat linear slide and extrusion frame for the bed. It’s not going anywhere.

So what weight were you thinking about? Most 3D printed stuff is around 10-20 grams and takes about half an hour (on an ultimaker) to print. That is never going to move with those (indeed massive overkill) linear slides.

Oooh it moves the bed for the Z axis! Wait didn’t the RepRap Darwin do that? Oh ya. It is cool not moving the X axis motor though!

I’ve never seen this H configuration before, its absolutely fascinating. Thanks for exposing me to this new design!

No problem, its nice to hear that someone likes this design. Its pretty nice indeed and most fun part is that it needs some figuring out how the hell it works :)

This H-belt-design looks really interesting. It seems you need less smooth rods for the x-y-axis than for exaple the Ultimaker and less bearings as well.

Does it have a particular disadvantage?

You need 6 idlers for belt placed in such way that belt is always parralel to smoothbars and itself, so all radiuses have to be exact. All those bends and lenght of belt byitself needs some force to move belt around, so you need more torque, thats why im using nema 23 1Nm motors.

Other than that o dont se any big disadvantages, its just less comon used design so had some design problems on the way.

I am working on a similar design for about 6 months now and i can tell you just by looking at your acceleration and speed(very low) in the vid that you have the common bed vibration/shaking problem associated with designing floating Z lift axis. Let us know if you find a solution to the problem other than software.

Low acceleration and speed are not related to mechanical design. Bed isnt shaking or anything like that. I had to lower those values becouse of deacceleration bug that Arthur is now fighting.

I’ve used the rails that are on the Z here, they are extremely sturdy, I don’t expect any bed vibration/shaking.

The low speed is indeed due to a problem we have in smoothie when combining high speeds and high step rates.

Have the issues with the H-bot configuration and high speed/high step rates for Smoothieboard been worked out?

It looks like it will be a nice printer when you get it all done. And thanks for mentioning the RA board in the article. http://www.elefu.com/index.php?route=product/product&product_id=51

Anyone wanting to see a bit more should search for the original inventor Ian Moyer,

There are two belts not one really long belt.

No, there is in fact one large belt. Take a look at CoreXY (http://corexy.com) & FoldaRap2 (http://www.reprap.org/wiki/FoldaRap2). The advantage of the CoreXY is that it eliminates moment forces in the moving carriage, at the cost of extra mechanical complexity & required belt length.

I am working on a printer extremely similar to the one presented here. Hopefully I get it moving by the end of next week.

“No, there is in fact one large belt. Take a look at CoreXY (http://corexy.com) & FoldaRap2 (http://www.reprap.org/wiki/FoldaRap2). The advantage of the CoreXY is that it eliminates moment forces in the moving carriage, at the cost of extra mechanical complexity & required belt length.”

Does CoreXY not use two belts? It looks like two to me…am I missing something?

CoreXY uses 2x belts.

He also built a portable CNC and CNC/3D printer: http://web.mit.edu/imoyer/www/portfolio/

3 d printer is a great invention

I am working on a 3d printer extremely similar to the one presented here. Hopefully I get it moving by the end of next week.

I built a somewhat simplified version of this printer

http://3dbotz.com/?product=3dbotz-m2-8×8-diy-kit

Love the design, I am making my own H-bot version, but using v-slot with no linear rods and using a 8″x12″ bed from maker farm.

3D printer super Love the design, I am making my own H-bot version, but using v-slot with no linear rods and using a 8″x12″ bed from maker farm.