Suction cup

A suction cup, also known as a sucker, is an object that uses the negative fluid pressure of air or water to adhere to nonporous surfaces, creating a partial vacuum.[1]

Suction cups are anatomical traits of some animals such as octopuses and squids, and have been reproduced artificially for numerous purposes.[2]

Theory[edit]

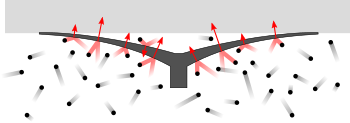

The working face of the suction cup is made of elastic, flexible material and has a curved surface.[3] When the center of the suction cup is pressed against a flat, non-porous surface, the volume of the space between the suction cup and the flat surface is reduced, which causes the air or water between the cup and the surface to be expelled past the rim of the circular cup. The cavity which develops between the cup and the flat surface has little to no air or water in it because most of the fluid has already been forced out of the inside of the cup, causing a lack of pressure. The pressure difference between the atmosphere on the outside of the cup and the low-pressure cavity on the inside of the cup keeps the cup adhered to the surface.

When the user ceases to apply physical pressure to the outside of the cup, the elastic substance of which the cup is made tends to resume its original, curved shape. The length of time for which the suction effect can be maintained depends mainly on how long it takes for air or water to leak back into the cavity between the cup and the surface, equalizing the pressure with the surrounding atmosphere. This depends on the porosity and flatness of the surface and the properties of the cup's rim.

Calculations[edit]

The force required to detach an ideal suction cup by pulling it directly away from the surface is given by the formula:

where:

- F is the force,

- A is the area of the surface covered by the cup,

- P is the pressure outside the cup (typically atmospheric pressure)

This is derived from the definition of pressure, which is:

For example, a suction cup of radius 2.0 cm has an area of  (0.020 m)2 = 0.0013 square meters. Using the force formula (F = AP), the result is F = (0.0013 m2)(100,000 Pa) = about 130 newtons.

(0.020 m)2 = 0.0013 square meters. Using the force formula (F = AP), the result is F = (0.0013 m2)(100,000 Pa) = about 130 newtons.

The above formula relies on several assumptions:

- The outer diameter of the cup does not change when the cup is pulled.

- No air leaks into the gap between the cup and the surface.

- The pulling force is applied perpendicular to the surface so that the cup does not slide sideways or peel off.

Artificial use[edit]

Artificial suction cups are believed to have first been used in the third century, B.C., and were made out of gourds. They were used to suction "bad blood" from internal organs to the surface. Hippocrates is believed to have invented this procedure.[citation needed]

The first modern suction cup patents were issued by the United States Patent and Trademark Office during the 1860s. TC Roche was awarded U.S. Patent No. 52,748 in 1866 for a "Photographic Developer Dipping Stick"; the patent discloses a primitive suction cup means for handling photographic plates during developing procedures. In 1868, Orwell Needham patented a more refined suction cup design, U.S. Patent No. 82,629, calling his invention an "Atmospheric Knob" purposed for general use as a handle and drawer opening means.[4][5]

Suction cups have a number of commercial and industrial applications:

- To affix objects to nonporous vertical surfaces such as refrigerator doors and tiled walls

- To move large smooth objects such as panes of glass, automobile windscreens and raised floor tiles

- In toys such as Nerf darts

- In toilet plungers[6]

- By urban climbers, to scale buildings with smooth exterior surfaces[7]

On May 25, 1981, Dan Goodwin, a.k.a. SpiderDan, scaled Sears Tower, the former world's tallest building, with a pair of suction cups. He went on to scale the Renaissance Center in Dallas, the Bonaventure Hotel in Los Angeles, the World Trade Center in New York City, Parque Central Tower in Caracas, the Nippon TV station in Tokyo, and the Millennium Tower in San Francisco.[8][9]

See also[edit]

References[edit]

- ^ ""Suction Cup" m-w.com". Merriam Webster: An Encyclopedia Britannica Company. Retrieved 2012-06-01.

- ^ "Well-Armed Design: 8 Octopus-Inspired Technologies". livescience.com. Retrieved July 30, 2015.

- ^ ""Suction Cup" google.com". Google Patents. Retrieved 2012-06-01.

- ^ "United States Patent 52,748".

- ^ "United States Patent 82,629".

- ^ "Internet Archive Wayback Machine". Web.archive.org. 2006-04-24. Archived from the original on April 24, 2006. Retrieved 2012-01-27.

- ^ "Man climbs skyscraper with suction cups". BBC News. 2010-09-07. Retrieved 2012-01-27.

- ^ http://www.youtube.com/watch?v=zKwRFwV5dHE

- ^ http://www.youtube.com/watch?v=SCMCEKy-zJE